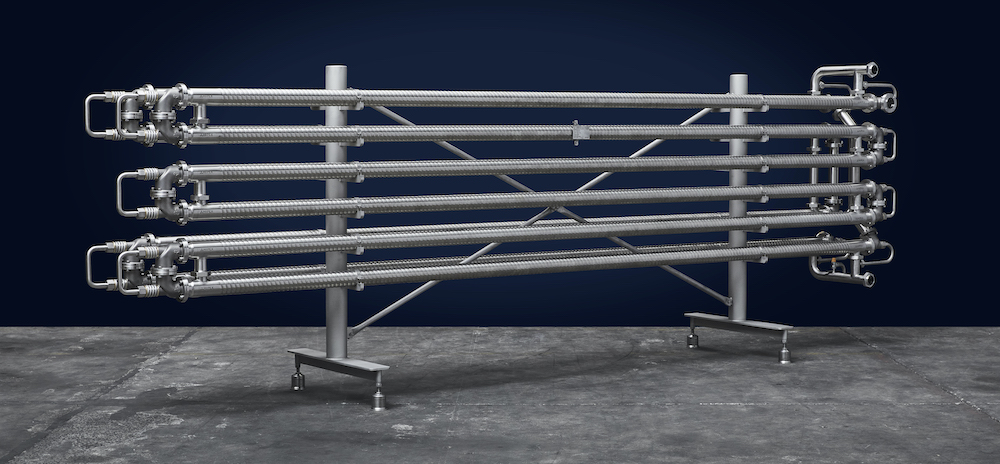

Hipex Mixchangers were developed for the most challenging products and provide unmatched thermal transfer performance on viscous products such as pastes and concentrates.

The Mixchanger is a triple-tube design in which the product flows through the anulus formed by the central mixing element and the inner tube. Simultaneously, the cooling or heating medium flows in the opposite direction through both the central mixing element and the shell’s jacket.

A specially designed central mixing element interacts with the Mixchanger’s inner tube to create continuous radial mixing in the product path. By carefully varying the size and shape of the removable central mixing element, it is possible to achieve the optimal degree of mixing. This means that it is well suited to virtually any application involving the heating or cooling of viscous products, with or without particulates.

The Mixchanger’s single product path design eliminates the risk of a blocked channel, which typically requires timely disassembly and manual cleaning. We have simplified the cleaning process as the unit is designed for CIP cleaning and the central mixing element can be easily removed for visual inspection of the heating surfaces on a periodic basis.

Originally intended for the processing of tomato and fruit pastes, the Mixchanger has several advantages over conventional multi- or monotube designs. Whereas most industries clean daily, our Mixchanger allows extended production runs, aseptically processing products for up to two weeks prior to cleaning. As a result, any slow-moving areas frequently burn into difficult-to-shift deposits in any stagnant areas. The Mixchanger was designed to eliminate these areas of slow flowing water where deposits are likely to form.

In addition to the many other critical high viscosity applications for the Mixchanger, today the majority of these Mixchanger units are sold to the dairy industry, specifically for the purpose of heating milk concentrate.

The Mixchanger’s thermal performance significantly reduces the amount of heat transfer surface area required, and with no moving parts and only a few static O-ring seals, the Mixchanger significantly reduces downtime and maintenance costs.

The Hipex Mixchanger provides significant benefits when processing viscous and high particulate products.

The inner tube is shaped to resemble a twisted mixing element to maximise heat transfer between the inner tube (the mixer) and the outer jacket. In comparison to a simple twisted flute placed inside a double tube heater, it is actively involved in heat transfer and does not cause parasitic pressure loss. As the inner tube is twisted, its cross-sectional area decreases, resulting in an increase in the cross-sectional area of the annuls, which reduces pressure loss below that caused by a similar corrugated or plain tube. Additionally, the twisted tube enhances CIP performance at all cleaning velocities.

In standard triple tube designs, the product entry and exit points are frequently sharp tees with a dead zone behind the direction of flow. This point is difficult to clean and frequently results in product burn on. These tee-like entries result in hard carbonised deposits that are impossible to clean in tomato pasteurising plants that have operated aseptically for weeks without cleaning. The Mixchanger header is swept to ensure that 100% of the product flow is parallel to the heat transfer surface prior to contact. This avoids dead and stagnant flow areas created by II tee features such as entry and exit ports. The design has been extensively validated in the dairy industry, specifically on milk concentrate heaters.

The spring serves two functions:

A / To account for thermal linear expansion due to temperature differentials between tube assemblies

B / To create tension within the inner tube, allowing it to float concentrically without the use of spacers

The traditionally used tube spacers in our experience, always cause a variety of problems. They are prone to galling during assembly and will occasionally wear completely through at contact points. Additionally, they are inspecting for product buildup and areas susceptible to crevice corrosion. The spring system used by Hipex has be proven to completely eliminate these problems.

All Mixchanger tubes are polished to a surface roughness of 0.8 Ra micrometres or better. The end header is a high-quality investment casting that has been internally polished to a grit of 180.

Viton is the most frequently used O-ring seal material in Mixchangers. These seals are obtained from the Newman Sanitary Gasket Company and come with an FDA compliance certificate. We have tested these and discovered that the compound is extremely resistant to both cleaning chemicals and compression set. The other frequently used seal material for triclamp termination seals is Teflon, which is available from Garlock. Again, they are FDA compliant and extremely resistant to compression set/creep, which is not the case with standard Teflon.

Numerous food products exhibit sheer thinning behaviour. There is always a risk that parallel paths used for heating purposes will plug up during operation. The Mixchanger system utilises a single product path to ensure proper flow distribution and cleaning, while allowing for a range of flow rates by adjusting the mixing element’s diameter and shape.

Copyright © 2023. Hipex Pty Ltd.